Ukwamkela itekhnoloji entsha yokuphosa ephucukileyo nesebenzayo, ukuphucula ukuzenzekelayo kwezixhobo zokuphosa, ngakumbi ukusetyenziswairobhothi yoshishinoitekhnoloji ye-automation, ngumlinganiselo ophambili wokukhupha amashishini ukuphumeza uphuhliso oluzinzileyo.

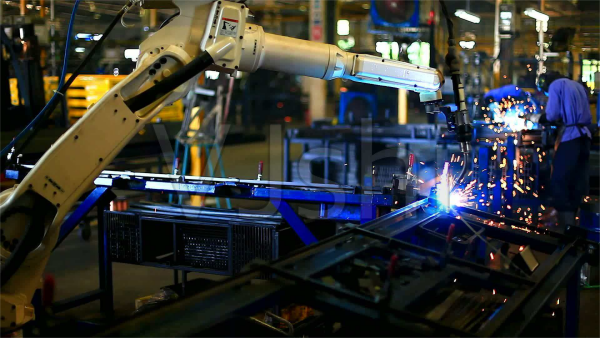

Kwimveliso yokuphosa,iirobhothi zoshishinoayinakuthatha indawo kuphela abantu abasebenza kwiqondo lokushisa eliphezulu, indawo engcolileyo kunye neyingozi, kodwa iphucula ukusebenza kakuhle, ukuphucula ukuchaneka kwemveliso kunye nomgangatho, ukunciphisa iindleko, ukunciphisa inkunkuma, kunye nokufumana iinkqubo eziguquguqukayo kunye nexesha elide lokuvelisa isantya esiphezulu. Indibaniselwano yendalo yezixhobo zokuphosa kunyeiirobhothi zoshishinoiye yagubungela imimandla eyahlukeneyo enje ngokuphosa ukufa, ukuphosa umxhuzulane, ukuphoswa koxinzelelo oluphantsi kunye nokuphosa isanti, ingakumbi ebandakanya ukwenziwa kondoqo, ukuphosa, ukucocwa, ukwenza oomatshini, ukuhlola, ukunyangwa komphezulu, uthutho kunye nokufakwa kweepaleti.

Iworkshop yeFoundry ibalasele ngakumbi, igcwele ubushushu obuphezulu, uthuli, ingxolo, njl., kwaye indawo yokusebenza inzima kakhulu. Iirobhothi zemizi-mveliso zinokusetyenziselwa ukuphosa umxhuzulane, ukuphoswa koxinzelelo oluphantsi, ukuphoswa koxinzelelo oluphezulu, ukuphonswa kwespin, ukugquma iindibano zocweyo ngeendlela ezahlukeneyo zokuphosa ezimnyama nezingeyontsimbi, kunciphisa kakhulu ukuqina kwabasebenzi.

Ngokweempawu zokusa, iiyunithi zerobhothi zomxhuzulane ezizenzelayo zineentlobo ngeentlobo zeefomathi zoyilo.

(1) Uhlobo lwesetyhula lufanelekile ukuphosa kunye neenkcukacha ezininzi, ukuphosa okulula, kunye neemveliso ezincinci. Umatshini ngamnye womxhuzulane unokuphosa iimveliso zeempawu ezahlukeneyo, kwaye isingqisho senkqubo sinokwahluka. Umntu omnye unokusebenzisa oomatshini ababini bokuxhuzula. Ngenxa yezithintelo ezimbalwa, yeyona ndlela isetyenziswa kakhulu ngoku.

(2) Uhlobo lwe-symmetrical lufanelekile ukuphosa kunye nezakhiwo zemveliso eziyinkimbinkimbi, i-sand cores, kunye neenkqubo eziyinkimbinkimbi zokuphosa. Ngokuhambelana nobukhulu be-castings, ii-castings ezincinci zisebenzisa oomatshini abancinci be-gravity. Amazibuko okugalela onke angaphakathi kwisetyhula yerobhothi yoshishino, kwaye irobhothi yoshishino ayihambi. Ukuphoswa okukhulu, ngenxa yokuba oomatshini be-gravity ehambelanayo bakhulu, i-robot ye-industrial idinga ukuxhotyiswa nge-axis ehambayo yokugalela. Kule ndlela, iimveliso zokuphosa zinokwahluka kwaye isigqi senkqubo sinokungahambelani.

(3) Ububi becala-by-icala setyhula kunye neentlobo symmetrical kukuba Logistics undoqo isanti iindawo ezingaphezulu kunye neendawo ezisezantsi ukuphosa isikhululo-sinye kwaye uthe saa, kunye nokusetyenziswa koomatshini bomxhuzulane ecaleni kusombulula le ngxaki. Inani loomatshini bomxhuzulane lilungelelaniswe ngokobungakanani bokujula kunye nesingqisho senkqubo, kwaye irobhothi yoshishino yenzelwe ukugqiba ukuba kufuneka ihambe. Abancedisi abancedisayo banokuqulunqwa ukuze bagqibezele umsebenzi wokubekwa kwesiseko sesanti kunye nokuphosa ukulayisha, ukufezekisa iqondo eliphezulu lokuzenzekelayo.

(4) Uhlobo lwesetyhula Isantya sokuphosa le modi sisebenza ngakumbi kuneendlela zangaphambili. Umatshini womxhuzulane ujikeleza eqongeni, kunye nezikhululo zokugalela, izikhululo zokupholisa, izikhululo zokukhulula, njl. I-robot yokugalela ngokuqhubekayo ithatha ulwelo lwe-aluminium ukugalela kwisikhululo sokuthulula, kwaye i-robot yokuchola ikhupha i-synchronously (inokwenziwa ngesandla, kodwa ngenxa yokusebenza kwayo okuphezulu, ukuqina komsebenzi kuphezulu kakhulu). Le modi ifaneleka kuphela ukuveliswa kwangaxeshanye kokuphoswa kweemveliso ezifanayo, iibhetshi ezinkulu, kunye neebhithi ezihambelanayo.

Xa kuthelekiswa noomatshini bokuphosa umxhuzulane, oomatshini bokuphosa abaphantsi koxinzelelo oluphantsi bakrelekrele ngakumbi kwaye bayazenzela, kwaye umsebenzi wezandla ufuna kuphela ukwenza umsebenzi oncedisayo. Nangona kunjalo, kwimodi yolawulo oluzenzekelayo, ngexesha lenkqubo yokuphosa, umsebenzi wezandla unokulawula umgca omnye ngumntu omnye kwaye udlale indima yokuhlola i-patrol. Ngoko ke, iyunithi engabonakaliyo yokuphosa uxinzelelo oluphantsi luyaziswa, kwaye iirobhothi zoshishino zigqiba wonke umsebenzi oncedisayo.

Kukho iindlela ezimbini zokusebenzisa iiyunithi zokuphosa zoxinzelelo oluphantsi ezingaqhutywanga:

1 Irobhothi yoshishino igqibezela yonke imisebenzi efana nokususwa kwemveliso, ukubekwa kwesihluzi, ukubala iinombolo zentsimbi, kunye nokususwa kwephiko, ngaloo ndlela iqonda ukuphosa okungekho mntu. Ngenxa yoyilo lwesithuba olwahlukeneyo, iirobhothi zemizi-mveliso zinokuxhonywa zijonge phantsi okanye zimiswe phantsi.

(2) Ukwenziwa kwee-castings kunye neenkcukacha zemveliso enye, ezifuna ukufakwa ngesandla kweentsimbi zesanti, kunye neebhetshi ezinkulu, iirobhothi zemizi-mveliso zithatha ngokuthe ngqo iinxalenye kumatshini woxinzelelo oluphantsi, zizipholise, okanye zibeke kumatshini wokugaya kwaye zidlulisele kwinkqubo elandelayo.

I-3) Ukwenziwa kwee-castings ezifuna i-sand cores, ukuba isakhiwo sesiseko sesanti silula kwaye isiseko sesanti sisodwa, iirobhothi zoshishino zingasetyenziselwa ukongeza umsebenzi wokuthatha kunye nokubeka i-sand cores. Ukufakwa ngesandla kweentsimbi zesanti kufuna ukungena kwi-mold cavity, kwaye iqondo lokushisa ngaphakathi kwesikhunta liphezulu kakhulu. Ezinye iicores zesanti zinzima kwaye zifuna uncedo lwabantu abaninzi ukugqiba. Ukuba ixesha lokusebenza lide kakhulu, iqondo lokushisa lokubumba liya kuhla, lichaphazela umgangatho wokuphosa. Ke ngoko, kuyafuneka ukuba kusetyenziswe iirobhothi zemizi mveliso ukuthatha indawo yokubeka isiseko sesanti.

Okwangoku, umsebenzi wangaphambili we-high-pressure casting, njengokuthulula kunye nokutshiza i-molds, ugqitywe ngeendlela eziphambili, kodwa ukukhutshwa kwe-castings kunye nokucocwa kweentloko zezinto eziphathekayo kwenziwa kakhulu ngesandla. Ngenxa yezinto ezifana nokushisa okuphezulu kunye nobunzima, ukusebenza kakuhle kwabasebenzi kuphantsi, nto leyo ethintela amandla okuvelisa umatshini wokuphosa. Iirobhothi zoshishino azikho kuphela ngokufanelekileyo ekuthatheni iinxalenye, kodwa kwangaxeshanye zigqibezele umsebenzi wokusika iintloko zezinto kunye neengxowa ze-slag, ukucoca amaphiko okubhabha, njl., ukusebenzisa ngokupheleleyo iirobhothi zoshishino ukunyusa imbuyekezo kutyalo-mali.

Ixesha lokuposa: Jul-08-2024