Ndiyakholwa ukuba wonke umntu uvileirobhothi. Ihlala ibonisa ubuchule bayo kwiimuvi, okanye yindoda ye-Iron Man yasekunene, okanye isebenze ngokuchanekileyo izixhobo ezahlukeneyo ezintsonkothileyo kwiifektri zetekhnoloji ezichanekileyo. Ezi ntelekelelo zentelekelelo zisinika umbono wokuqala kunye nomdla malungairobhothi. Ke yintoni irobhothi yokuvelisa ishishini?

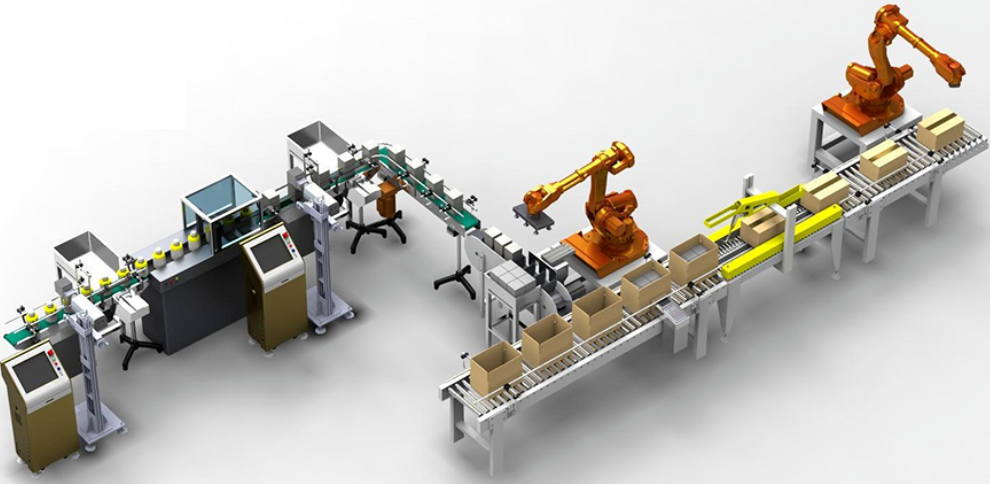

Anirobhothi yokuvelisa ishishinisisixhobo esinomatshini esinokwenza ngokuzenzekelayo imisebenzi. Inokuxelisa ezinye iintshukumo zeengalo zabantu kwaye yenze imisebenzi efana nokuphatha izinto, ukusetyenzwa kwamalungu, kunye nokudibanisa imveliso kwindawo yokuvelisa kwimizi-mveliso. Umzekelo, kwiworkshop yokwenziwa kweemoto, irobhothi inokubamba ngokuchanekileyo iinxalenye zemoto kwaye izifake kwindawo echaziweyo. Iirobhothi zokwenziwa kwemizi-mveliso zihlala zixhotyiswa zizixhobo zokuqhuba ezinje ngeenjini, iisilinda, kunye neesilinda zehydraulic. Ezi zixhobo zokuqhuba zihambisa amalungu erobhothi phantsi komyalelo wenkqubo yokulawula. Inkqubo yolawulo ikakhulu yenziwe ngumlawuli, inzwa, kunye nesixhobo sokucwangcisa. Umlawuli "yingqondo" yerobhothi, efumana kwaye isebenze imiyalelo eyahlukeneyo kunye nemiqondiso. Uluvo lusetyenziselwa ukubona indawo, isantya, amandla, kunye nolunye ulwazi lobume berobhothi. Ngokomzekelo, ngexesha lenkqubo yendibano, i-sensor yamandla isetyenziselwa ukulawula amandla endibano ukuphepha umonakalo kwiindawo. Isixhobo sokucwangcisa sinokuba yiprogram yokufundisa okanye isoftware yeprogram yekhompyuter, kwaye i-motion trajectory, ulandelelwano lwezenzo kunye neeparamitha zokusebenza ze-manipulator zinokusetwa ngeprogramming. Ngokomzekelo, kwimisebenzi ye-welding, indlela yokunyakaza kunye neeparitha ze-welding zentloko ye-welding manipulator, njengesantya se-welding, ubukhulu bangoku, njl., inokusetwa ngeprogram.

Iimpawu ezisebenzayo:

Ukuchaneka okuphezulu: Inokubeka ngokuchanekileyo kwaye isebenze, kwaye impazamo inokulawulwa kwi-millimeter okanye nakwizinga le-micron. Ngokomzekelo, ekwenzeni izixhobo ezichanekileyo, i-manipulator inokudibanisa ngokuchanekileyo kwaye iqhube iinxalenye.

Isantya esiphezulu: Inokugqiba ngokukhawuleza izenzo eziphindaphindiweyo kunye nokuphucula ukusebenza kakuhle kwemveliso. Ngokomzekelo, kumgca wemveliso yokupakisha ngokuzenzekelayo, i-manipulator inokukhawuleza ukubamba iimveliso kwaye ifake kwiibhokisi zokupakisha.

Ukuthembeka okuphezulu: Inokusebenza ngokuzinzileyo ixesha elide kwaye inciphise iimpazamo ezibangelwa yimiba enjengokukhathala kunye neemvakalelo. Xa kuthelekiswa nomsebenzi wezandla, kwezinye iindawo zokusebenza ezinzima, ezifana nobushushu obuphezulu, ubuthi, kunye nobukhulu obuphezulu, i-manipulator inokusebenza ngokuqhubekayo.

Ukuguquguquka: Imisebenzi yayo yokusebenza kunye neendlela zokuhamba zingatshintshwa ngokucwangcisa ukulungelelanisa iimfuno ezahlukeneyo zemveliso. Ngokomzekelo, i-manipulator efanayo inokwenza i-high-speed material handling kwixesha lemveliso ephezulu kunye nokudibanisa okulungileyo kweemveliso kwixesha elingekhoyo.

Zeziphi iindawo zokusetyenziswa kwee-manipulators zokwenziwa kwemizi-mveliso?

Ishishini lokuVelisa iimoto

UkuPhathwa kwamacandelo kunye neNdibano: Kwimigca yemveliso yeemoto, iirobhothi zinokuthwala ngokufanelekileyo iinxalenye ezinkulu ezinjengeenjini kunye nokuhanjiswa kwaye zidibanise ngokuchanekileyo kwi-chassis yemoto. Ngokomzekelo, i-robot ye-axis emithandathu inokufakela isihlalo semoto kwindawo echaziweyo kumzimba wemoto ngokuchaneka okuphezulu kakhulu, kwaye ukuchaneka kwendawo yayo kunokufikelela ku-± 0.1mm, ukuphucula kakhulu ukusebenza kwendibano kunye nomgangatho. I-Welding Operation: Umsebenzi we-welding womzimba wemoto ufuna ukuchaneka okuphezulu kunye nesantya. Irobhothi inako ukuwelda iindawo ezahlukeneyo zesakhelo somzimba kunye isebenzisa itekhnoloji ye-welding okanye i-arc welding ngokwendlela ecwangciswe kwangaphambili. Ngokomzekelo, i-robot yokuvelisa i-industrial inokugqiba i-welding ye-car door frame kwi-1-2 imizuzu.

Ishishini loMbane kunye noMbane

Ukwenziwa kweBhodi yeSekethe: Ngexesha lokuveliswa kweebhodi zeesekethe, iirobhothi zinokufaka izinto ze-elektroniki. Inokuthi ifake ngokuchanekileyo amacandelo amancinci anje nge-resistors kunye ne-capacitors kwiibhodi zesekethe ngesantya samanani amaninzi okanye amashumi amaninzi ngomzuzwana. INdibano yeeMveliso: Kwindibano yeemveliso ze-elektroniki, ezinjengeefowuni eziphathwayo kunye neekhompyuter, iirobhothi zinokugqiba imisebenzi efana nendibano yeqokobhe kunye nokufakwa kwesikrini. Ukuthatha indibano yefowuni yeselula njengomzekelo, i-robot inokufaka ngokuchanekileyo amacandelo afana nezikrini zokubonisa kunye neekhamera kumzimba wefowuni ephathwayo, ukuqinisekisa ukuhambelana kunye nomgangatho ophezulu wokuhlanganisa imveliso.

Ishishini lokulungisa oomatshini

Ukulayisha kunye nokukhulula imisebenzi: Phambi kwezixhobo zoomatshini be-CNC, oomatshini bokubetha kunye nezinye izixhobo zokusebenza, i-robot inokwenza umsebenzi wokulayisha kunye nokukhulula. Inokukhawuleza ibambe izinto ezingenanto kwi-silo kwaye iyithumele kwi-workbench yezixhobo zokusebenza, kwaye emva koko ikhuphe imveliso egqityiweyo okanye imveliso egqityiweyo emva kokulungiswa. Ngokomzekelo, xa i-CNC lathe iqhuba iindawo ze-shaft, i-robot inokugqiba umsebenzi wokulayisha kunye nokukhupha yonke imizuzwana ye-30-40, ephucula izinga lokusetyenziswa kwesixhobo somatshini. Uncedo lokulungisa inxenye: Ekuqhubekeni phambili kwezinye iindawo ezintsonkothileyo, irobhothi inokuncedisa ekujikeni nasekubekeni iindawo. Ngokomzekelo, xa kusetyenzwa i-molds eyinkimbinkimbi enobuso obuninzi, i-robot inokuguqula i-mold kwi-angle efanelekileyo emva kokuba inkqubo enye igqityiwe ukulungiselela inkqubo elandelayo, ngaloo ndlela iphucula ukusebenza kunye nokuchaneka kwenxalenye yokucubungula.

Ishishini lokutya nesiselo

Imisebenzi yokupakisha: Kwikhonkco lokupakisha lokutya kunye neziselo, irobhothi inokubamba imveliso kwaye iyifake kwibhokisi yokupakisha okanye kwingxowa yokupakisha. Ngokomzekelo, kumgca wokuvelisa isiselo, irobhothi inokubamba kwaye ipakishe iibhotile ze-60-80 zeziselo ngomzuzu, kwaye inokuqinisekisa ukucoceka kunye nomgangatho wokupakisha.

Umsebenzi wokuhlela: Ukuhlela ukutya, okufana nokuhlelwa kunye nokuhlelwa kweziqhamo kunye nemifuno, irobhothi inokuhlelwa ngokobungakanani, ubunzima, umbala kunye nezinye iimpawu zemveliso. Kwinkqubo yokukhetha emva kokuba isiqhamo sivunwa, irobhothi inokubona iziqhamo ezikumgangatho ohlukeneyo kwaye izibeke kwiindawo ezahlukeneyo, nto leyo ephucula ukusebenza kakuhle kokuhlelwa kunye nomgangatho wemveliso.

Amalungiselelo kunye neshishini lokugcina impahla

Ukuphatha imithwalo kunye ne-palletizing: Kwindawo yokugcina impahla, irobhothi inokuthwala iimpahla zeemilo ezahlukeneyo kunye nobunzima. Inokususa iimpahla kwiishelufa okanye ibeke iimpahla kwiipalethi. Umzekelo, izixhobo ezinkulu kunye neerobhothi zokugcina iimpahla zinokuthwala iimpahla ezinobunzima beetoni ezininzi, kwaye zinokupakisha iimpahla kwiziqwenga ezicocekileyo ngokwemigaqo ethile, nto leyo ephucula ukusetyenziswa kwendawo yokugcina impahla. Ukuhlelwa kweodolo: Kwiimeko ezifana ne-e-commerce logistics, i-robot inokulungelelanisa iimpahla ezihambelanayo kwiishelufu zendawo yokugcina impahla ngokolwazi lwe-odolo. Iyakwazi ukuskena ngokukhawuleza ulwazi lwemveliso kwaye ibeke ngokuchanekileyo iimveliso kwibhanti yokuhambisa yokuhlela, ukukhawulezisa ukusetyenzwa kwe-odolo.

Ziziphi iimpembelelo ezithile zokusetyenziswa kwee-manipulators zokuvelisa kwimizi-mveliso ekusebenzeni ngokufanelekileyo kwemveliso yeshishini?

Ukuphucula isantya semveliso

Ukuphindaphinda okukhawulezileyo: Ii-manipulators zokwenziwa kwemizi-mveliso zinokwenza umsebenzi ophindaphindiweyo ngesantya esiphezulu ngaphandle kokudinwa kunye nokunciphisa ukusebenza kakuhle njengokusebenza ngesandla. Umzekelo, kwinkqubo yokudityaniswa kwamacandelo e-elektroniki, i-manipulator inokugqiba ezininzi okanye amakhulu okuxhwila kunye nokufakwa kwezenzo ngomzuzu, ngelixa umsebenzi wezandla unokugqitywa amaxesha ambalwa ngomzuzu. Ukuthatha imveliso yefowuni yeselula njengomzekelo, inani lezikrini ezifakwe ngeyure usebenzisa i-manipulators ingaba ngamaxesha angama-3-5 ngaphezu kokufakwa ngesandla. Ukunciphisa umjikelezo wemveliso: Ekubeni i-manipulator inokusebenza iiyure ezingama-24 ngosuku (ngokugcinwa okufanelekileyo) kwaye inesantya sokuguqula ngokukhawuleza phakathi kweenkqubo, inciphisa kakhulu umjikelezo wemveliso yemveliso. Umzekelo, kwimveliso yeemoto, ukusebenza ngokufanelekileyo kwe-manipulator kwi-welding yomzimba kunye ne-parts assembly links kunciphise ixesha lokudityaniswa kwemoto ukusuka kwiiyure ezininzi ukuya kwiiyure ezingaphezu kweshumi ngoku.

Ukuphucula umgangatho wemveliso

Ukusebenza okuchanekileyo okuphezulu: Ukuchaneka komsebenzi we-manipulator kuphezulu kakhulu kunokusebenza kwesandla. Kwi-machining echanekileyo, i-robot inokulawula ukuchaneka kwe-machining yamacandelo kwinqanaba le-micron, okunzima ukuyifumana ngokusebenza ngesandla. Umzekelo, kwimveliso yamacandelo ewotshi, irobhothi inokugqiba ngokuchanekileyo ukusika kunye nokusila iindawo ezincinci ezinje ngegiya, iqinisekisa ukuchaneka komda kunye nokugqitywa komphezulu wamalungu, ngaloo ndlela iphucula umgangatho wemveliso.

Uzinzo olusemgangathweni olulungileyo: Ukuhambelana kwayo kwesenzo kulungile, kwaye umgangatho wemveliso awuyi kuguquguquka ngenxa yezinto ezifana neemvakalelo kunye nokudinwa. Kwinkqubo yokupakishwa kweziyobisi, irobhothi inokulawula ngokuchanekileyo idosi yechiza kunye nokutywinwa kwepakethe, kwaye umgangatho wepakethe nganye unokuhambelana kakhulu, unciphise izinga elineziphene. Ngokomzekelo, ekupakishweni kokutya, emva kokusebenzisa i-robot, izinga lokulahlekelwa kwemveliso elibangelwa ukupakishwa okungafanelekanga lingancitshiswa ukusuka kwi-5% - 10% ekusebenzeni ngesandla ukuya kwi-1% - 3%.

Lungiselela inkqubo yemveliso

Ukuhlanganiswa kwenkqubo ezenzekelayo: I-robot ingakwazi ukudibanisa kunye nezinye izixhobo ezizenzekelayo (ezifana nemigca yokuvelisa ngokuzenzekelayo, iinkqubo zokugcina ngokuzenzekelayo, njl.) Ukwandisa yonke inkqubo yokuvelisa. Kumgca wemveliso yeemveliso ze-elektroniki, i-robot inokudibanisa ngokusondeleyo imveliso, ukuvavanywa kunye nokuhlanganisa iibhodi zeesekethe ukufezekisa imveliso eqhubekayo ngokuzenzekelayo ukusuka kwizinto eziluhlaza ukuya kwiimveliso ezigqityiweyo. Ngokomzekelo, kwi-workshop yokuvelisa i-motherboard epheleleyo yekhompyutheni, i-robot inokulungelelanisa izixhobo ezahlukeneyo zokucwangcisa ukugqiba uluhlu lweenkqubo ezivela kwimveliso yeebhodi zesekethe eziprintiweyo ukuya kufakelo lwe-chip kunye ne-welding, ukunciphisa ixesha lokulinda kunye nokungenelela kwabantu kwi-intermediate links. Ukulungelelaniswa komsebenzi oguquguqukayo: Imisebenzi yomsebenzi werobhothi kunye nomyalelo womsebenzi unokulungiswa ngokulula ngokucwangcisa ukulungelelanisa iimfuno ezahlukeneyo zemveliso kunye nokutshintsha kwemveliso. Kwimveliso yempahla, xa isitayela sitshintsha, kuphela inkqubo yerobhothi kufuneka iguqulwe ukuze ilungelelanise ukusika, ukuthunga uncedo kunye neminye imisebenzi yendlela entsha yokugqoka, ephucula ukuguquguquka kunye nokulungelelanisa inkqubo yokuvelisa.

Ukunciphisa iindleko zemveliso

Ukunciphisa iindleko zabasebenzi: Nangona utyalo-mali lokuqala lwerobhothi luphezulu, ekuhambeni kwexesha, lungathatha indawo yesixa esikhulu somsebenzi wezandla kunye nokunciphisa inkcitho yeendleko zomsebenzi wenkampani. Umzekelo, inkampani eyenza amathoyizi esebenza kakhulu inokunciphisa i-50% -70% yabasebenzi bendibano emva kokwazisa iirobhothi zokuhlanganisa ezinye iindawo, ngaloo ndlela igcina imali eninzi kwiindleko zabasebenzi. Ukunciphisa izinga le-scrap kunye nokulahlekelwa kwezinto eziphathekayo: Ngenxa yokuba i-robot inokusebenza ngokuchanekileyo, iyanciphisa ukuveliswa kwe-scrap ebangelwa yimpazamo yokusebenza, kwaye iyanciphisa nokulahlekelwa kwezinto. Ngethuba lenkqubo yokuthabatha kunye nokulungisa iimveliso ezibunjiweyo ze-injection, i-robot inokubamba ngokuchanekileyo iimveliso ukuze ugweme umonakalo wemveliso kunye nokuchithwa okugqithiseleyo kwezinto ezilahliweyo, ukunciphisa izinga le-scrap nge-30% - 50% kunye nokulahlekelwa kwezinto eziphathekayo ngama-20% - 40%.

Ixesha lokuposa: Jan-21-2025