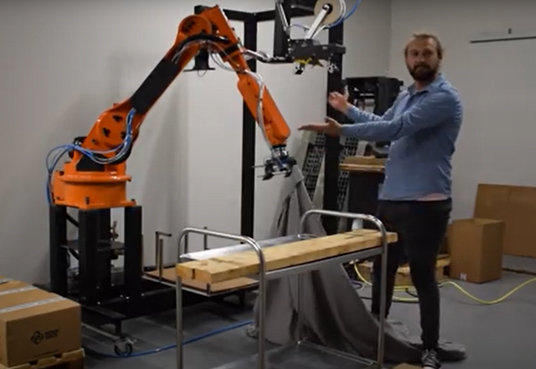

Ukupakishwairobhothisisixhobo esiphambili, esikrelekrele, kunye nesixhobo somatshini esisebenza kakhulu, esibandakanya ikakhulu iinkqubo zokubona izinto ezikrelekrele, ii-manipulators zokupakisha, ii-manipulators zokuphatha, iinkqubo zokupakisha kunye neenkqubo zokulawula, njl. Ineenzuzo zokusebenza okuphezulu kunye nokusebenza okuchanekileyo, okunokugcina ngokufanelekileyo abasebenzi, ixesha kunye nezinye iindleko, kwaye isetyenziswe ngokubanzi kwishishini lokutya. Ukuhlelwa kweiirobhothi zokupakisha

Ukupakishwa kwemveliso ngokubanzi kuneendlela ezininzi. Ngokwemilo, izinto eziphathekayo, ubunzima kunye neemfuno zokucoceka kwento, inkqubo yokupakisha inzima kakhulu. Okwangoku, kukho ezi ntlobo zilandelayo zerobhothi zale nkqubo yokupakisha:

I-robot ye-Bagging: I-robot ye-bagging luhlobo olusisigxina olujikelezayo kunye nomzimba ojikelezayo we-360-degree. Irobhothi igqibezela ukuthuthwa, ukuvulwa kwengxowa, ukulinganisa, ukuzalisa, ukuthunga ingxowa kunye nokupakishwa kwengxowa yokupakisha. Le irobhothi yokupakisha ekrelekrele kakhulu. Irobhothi yomdlalo wamanqindi: Ngokufana nerobhothi ephethe ibhegi, ibhokisi yentsimbi kunye nezikhongozeli zokupakisha zeglasi zigqityezelwa yirobhothi eqinileyo. Kukho iindidi ezimbini zoomatshini kunye neentlobo zokufunxa umoya zokubamba ukupakishwa kwebhokisi. Iyakwazi ukuhamba iyonke. Bamba okanye ubhengeze ipakethe, uze uyithumele kwibhokisi yokupakisha okanye kwipalethi kwindawo echongiweyo. Inomsebenzi wolwalathiso oluzenzekelayo kunye nokulungelelaniswa kwesikhundla, kwaye ingakwazi ukuqonda ukukhulula kunye nokulungelelaniswa kwesikhokelo ngaphandle kwebhokisi (i-pallet). Olu hlobo lwerobhothi yirobhothi esele ikhulile ngokwentelekiso enoluhlu olubanzi lwezicelo. Njengeziselo, ibhiya, njl.

Irobhothi yokuzalisa: Le irobhothi elinganisa, iikepusi, icinezela (izikrufu) kwaye ichonge emva kokuba isingxobo sokupakisha sizaliswe ngezinto ezingamanzi. Inemisebenzi yokungabikho kokutya ngaphandle kweebhotile, akukho ukutya ngaphandle kwee-caps, i-alarm yebhotile ephukile kunye nokugatywa ngokuzenzekelayo. Kwixesha elidlulileyo, ezininzi zezinto zethu zamanzi zazizaliswe ngokukodwa ngumsebenzi wendawo yale robot-i-manipulator ifakwe kumgca wokuvelisa. Ngoku, le robhothi iqwalaselwe ngokuthe ngqo ngasemva komkhosi wokuvelisa izinto ukuze iqonde ukuzaliswa kwayo ngokuzenzekelayo. Iirobhothi zokuzalisa zahlulwe zibe yipakethe ethambileyo kunye nokupakishwa kanzima. I-robot yokupakisha enzima (ibhotile) yokuzalisa ihlalutywa apha.

Irobhothi ehambisa ukupakishwa: Olu hlobo lwerobhothi kwishishini lokupakisha lubhekisa ikakhulu kwirobhothi esetyenziselwa ukupakisha iibhotile zeplastiki kunye nokuhambisa. Isebenzisa amandla kunye namacandelo akhethekileyo ukuqonda ukuhanjiswa kweebhotile (iibhotile ezingenanto), ngokukhawuleza iziphumo kunye nokulungelelanisa iibhotile zokupakisha kwibhotile yebhotile, kwaye emva koko inika amandla athile (isalathiso, ubukhulu). Yenza umzimba webhotile udlule ngokuchanekileyo kwindlela yeparabola emoyeni ukuze ufikelele kwindawo yokusebenza yokuzalisa. Le robhothi itshintsha indlela yesiqhelo yokuhambisa ibhotile. Ikhawulezisa isantya sokuhambisa kwaye inciphisa indawo yokuhambisa. Yirobhothi yokupakisha enengcamango entsha. Isebenzisa i-aerodynamics kunye nezixhobo ezikhethekileyo zoomatshini ukufezekisa umsebenzi wayo wokuhambisa.

Izinto eziluncedo zokupakisha iirobhothi

1. Ukuchaneka kwemveliso Ingalo yerobhothi ifakwe ngokusisigxina kwisiseko somatshini oqinileyo, kwaye i-axes ye-robot ye-multi-axis ijikelezwa yi-servo motors kunye neegesi, eziqinisekisa ukuba i-robot inokuguquguquka kwaye inqume ngokukhululekile indawo yokusebenza ngaphakathi kwendawo yokusebenza.

2. Ukusebenza ngokulula Inkqubo ilawula i-robot, i-mechanical gripper kunye ne-conveyor belt nge-PLC, kwaye inkqubo ixhotywe ngesikrini esikhethekileyo sokuthintela ukubonisa ulwazi ngexesha lenkqubo yokuvelisa. Inkqubo ithatha ujongano oluphambili lomatshini wobuntu, kwaye abaqhubi banokuguqula ngokulula iiparamitha kwaye bakhethe iinkqubo kwi-interface.

3. Ukuguquguquka kwemveliso I-robot gripper ifakwe kumbindi weflange. Inokuthi iyilwe njengesixhobo esisisigxina okanye sitshintshwe ngeendlela ezahlukeneyo zokubamba ngesixhobo sokutshintsha ngesandla ngokuzenzekelayo ukulungelelanisa kwimisebenzi ekhethekileyo. I-robot inokutshintsha kwaye ifake ii-grippers ezahlukeneyo ngokweemfuno zeyona nkqubo yokuvelisa imveliso ukuhlangabezana neemfuno zemveliso eguquguqukayo. Irobhothi inokusebenzisana nenkqubo yokuhlola okubonwayo yelaser ukuchonga uhlobo lomsebenzi kunye nokunceda irobhothi iwufumane umsebenzi.

Iimpawu zokupakisha iirobhothi

1. Ukusetyenziswa okunamandla: Xa ubukhulu, umthamo, imilo kunye nemilinganiselo yangaphandle yeemveliso eziveliswa yinguqu yeshishini, kufuneka ukuguqulwa okuncinci kuphela kwisikrini sokuchukumisa, esingayi kuchaphazela ukuveliswa kwesiqhelo kweshishini. Ukutshintsha kweepalletizer zoomatshini bemveli kuyingxaki okanye akunakwenzeka. 2. Ukuthembeka okuphezulu: I-robot yokupakisha inokuhlala igcina imo efanayo ngexesha lokusebenza ngokuphindaphindiweyo, kwaye akuyi kubakho ukuphazamiseka kwe-subjective efana neyomntu, ngoko ukuthembeka kwayo komsebenzi kuphezulu.

3. Iqondo eliphezulu lokuzenzekelayo: Ukusebenza kwe-robot yokupakisha kuxhomekeke kulawulo lweprogram, ngaphandle kokuthatha inxaxheba komntu, kunye neqondo eliphezulu lokuzenzekelayo, ukulondoloza umsebenzi omningi.

4. Ukuchaneka okulungileyo: Ukulawulwa komsebenzi we-robot yokupakisha kuchanekile, kwaye impazamo yendawo yayo iphantsi kwenqanaba le-millimeter, ngokuchaneka okuhle kakhulu.

5. Ukusetyenziswa kwamandla aphantsi: Ngokuqhelekileyo amandla e-palletizer yomatshini ajikeleze i-26KW, ngelixa amandla e-robot yokupakisha ajikeleze i-5KW, enciphisa kakhulu iindleko zokusebenza zabathengi.

6. Uluhlu olubanzi lwezicelo: I-robot yokupakisha isetyenziswa kakhulu. Inokugqiba imisebenzi emininzi enje ngokubamba, ukuphatha, ukulayisha kunye nokukhulula, kunye nokupakisha.

7. Ukusebenza okuphezulu: Isantya sokusebenza kwerobhothi yokupakisha ikhawuleza kwaye akukho kuphazamiseka kwexesha, ngoko ukusebenza kwayo kuphezulu kakhulu.

8. Unyawo oluncinci: I-robot yokupakisha inokusekwa kwindawo emxinwa kwaye ingasetyenziswa ngokufanelekileyo, ehambelana nokuhlelwa komgca wokuvelisa kwifektri yomthengi kwaye inokushiya indawo enkulu yokugcina impahla.

Kule mihla, ishishini lokupakisha liye langena ngokuthe ngcembe kwixesha le-automation. Njengombonakaliso okhuphisanayo wetekhnoloji ye-automation, iirobhothi zamashishini zifaneleke kakhulu kwiinkqubo eziphindaphindayo, ezikhawulezayo, ezichanekileyo neziyingozi. Ukusetyenziswa kweerobhothi zokupakisha akunakunciphisa iindleko kuphela, kodwa kuzisa ukuguquguquka okusebenzayo ngakumbi. Akunjalo kuphela ukupakisha iirobhothi zoshishino, iinkampani ezininzi zikhetha ukusebenzisa iintlobo ezahlukeneyo zeerobhothi zemizi-mveliso ngenxa yokuguquguquka kwazo kunye nokuthembeka. Kwixesha elizayo, iirobhothi zamashishini ziya kuthatha indawo yezixhobo zemveli kwaye zibe yenye yezona zinto zibalulekileyo zokuqhuba uphuhliso lweenkalo ezahlukeneyo.

Ixesha lokuposa: Nov-20-2024